Aluminum Casters — Lightweight With a Load of Benefits.

AEROL Co. is the first manufacturer to produce all aluminum wheels, casters, and aircraft running gear. We maintain highly critical quality control standards through every manufacturing phase to ensure all our products are up to spec.

This brings us to why aluminum is so prominent in Aerol casters.

Aluminium casters are significant in the aerospace, military, and ground support industries. As a lightweight and robust material, aluminum is ideal for applications where weight and strength are critical factors. The aerospace industry commonly uses Cast aluminum parts for various applications, including aircraft components, rocket engines, and satellite parts.

Aluminium casters are significant in the aerospace, military, and ground support industries. As a lightweight and robust material, aluminum is ideal for applications where weight and strength are critical factors. The aerospace industry commonly uses Cast aluminum parts for various applications, including aircraft components, rocket engines, and satellite parts.

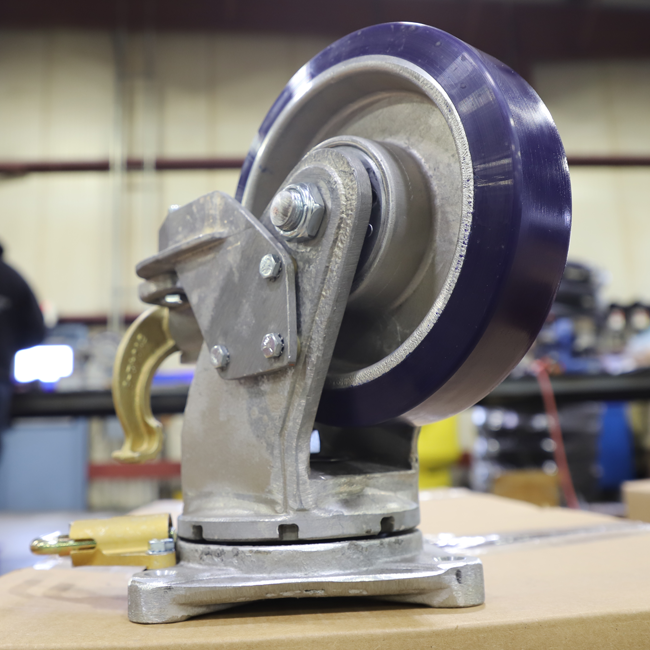

Aerol engineers and metallurgists selected #356 aluminum as the go-to material to produce wheels and casters. This Heavy-duty aluminum caster is the most suitable material because of its high corrosion resistance, tensile strength, and uniform sectional properties. In addition, the adaptability of aluminum to permanent mold casting provides the ultimate in modern materials handling media.

The benefits of aluminum casters.

- Corrosion resistance. Aluminum casters are ideal in wet and humid environments and outdoor use, many conditions faced by carts and equipment in the aerospace, military, and ground support industries. They also function exceptionally in non-sparking and non-magnetic situations.

- Aesthetics. If you operate in a public-facing environment, aesthetics are important. Aluminum is more visually appealing than steel or iron and maintains a clean, crisp appearance for its entire lifespan when properly maintained.

- Minimize damage. Aluminum spring-loaded casters minimize injury sustained during indoor or outdoor transport by absorbing impact and load movement.

Other factors to consider when choosing an Aerol aluminum caster.

Safety: In military and aerospace applications, the demands on safety are high due to the nature of the work. Using Aerol casters ensures high security by providing reliable and durable equipment for transporting heavy loads and aircraft components. Failure in a caster has catastrophic consequences, which is why Aerol casters are built to withstand their demands.

Durability: Aerospace components are often subjected to extreme conditions, including high temperatures, heavy loads, and chemical exposure. Aluminum casters are designed to withstand these conditions and provide long-lasting performance, reducing the need for frequent replacement and repair.

Durability: Aerospace components are often subjected to extreme conditions, including high temperatures, heavy loads, and chemical exposure. Aluminum casters are designed to withstand these conditions and provide long-lasting performance, reducing the need for frequent replacement and repair.

Precision: Many aerospace and military components require precise handling and positioning during transportation. Aerol casters with features like swivel locks and brakes can help ensure accurate positioning, improving safety and efficiency.

You’ll find Aerol casters in many commercial and military applications, and all meet MIL-C-4751, MS24373, MS27281, MS27149, MS24374, and MIL-C-7474 specifications.